In the production of home goods like PP pillows, floor mats, and placemats, “waste” is an unavoidable challenge for all manufacturers and brands. Often, the root cause lies not in post-production cutting techniques, but in the initial selection of fabric width. As raw material and operational costs continue to rise, the ability to reduce waste at the source becomes the key to building lasting trust and partnerships.

The logic of traditional supply chains is straightforward: fabric suppliers provide rolls of material in fixed widths, and customers plan their cutting layouts around these predetermined dimensions. This seemingly clear division of labor often traps production in a dilemma: while the fabric quality is excellent, layout constraints become a constant struggle—the width is always just a bit too narrow for efficient utilization, leaving unusable remnants after cutting. Over time, these seemingly minor losses accumulate, getting spread across the cost of each finished product and eroding the company's precious profit margins.

The Fixed Width Dilemma: When Standard Sizes Meet Limited Fabric Widths

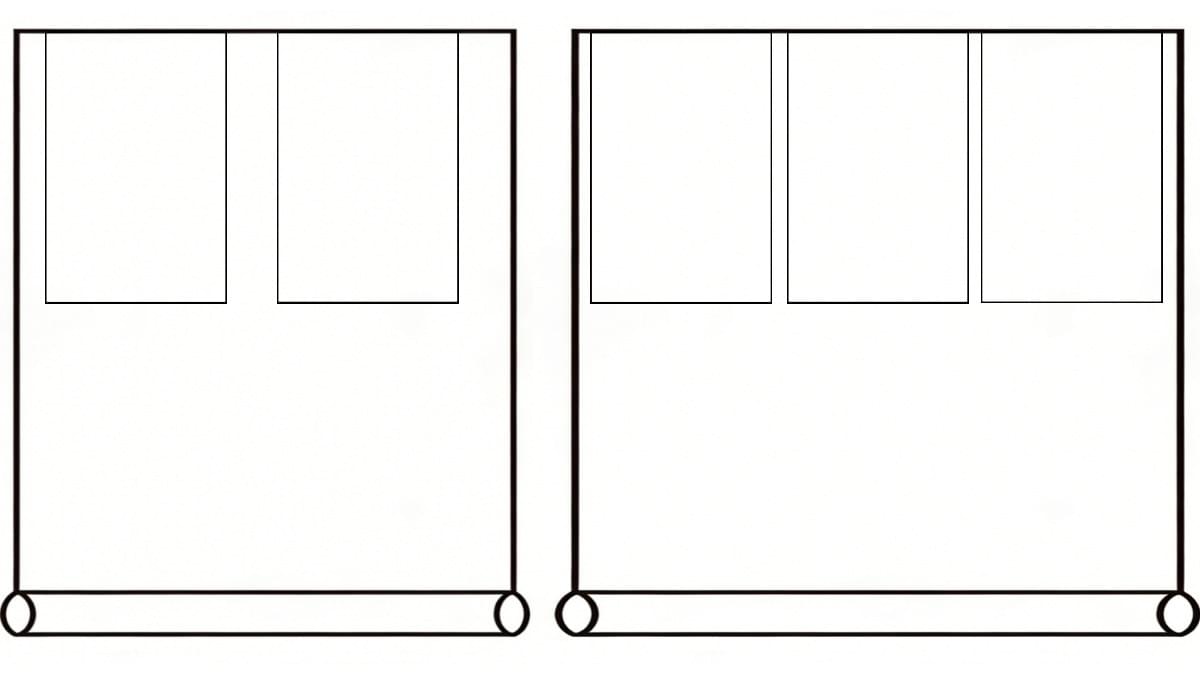

Consider the standard product dimensions prevalent in European and American markets: floor mats typically measure 40×60 cm or 50×80 cm, placemats adhere to the standard 30×45 cm, while throw pillows commonly come in 45×45 cm or 30×50 cm sizes. While finished dimensions have become established standards, if fabric widths are limited to only a few fixed options, layout planning becomes a mathematical game of constant compromise. No matter how meticulously you arrange the pieces, unusable scraps inevitably result.

Never underestimate the impact of fabric waste. When production scales reach supermarket order levels—with batches routinely numbering tens of thousands or even hundreds of thousands of pieces—reducing the waste rate by just a few percentage points can yield substantial cost savings. These savings can either directly translate into corporate profits or serve as a competitive pricing advantage in the marketplace.

Shift Your Thinking: Tailor Fabric Width to Your Product

If we shift our mindset away from the traditional approach of “using whatever fabric is available” and instead adopt a new model of “customizing fabric widths based on the product,” we can significantly reduce waste at the source. This is particularly meaningful for clients with consistently popular sizes.

Imagine this: Suppose you primarily produce 40×60 cm floor mats. By slightly adjusting the fabric width, your layout could shift from two pieces per row to three. This means more products can be cut from the same roll of fabric. For you, it translates to direct cost savings; for us at Eswoven, it means leveraging our technical expertise to create an additional profit margin for you.

Flexible and Adjustable Fabric Width Production Capability: Precise Matching from 1.4m to 3.2m

Many fabric suppliers can only offer fixed widths due to limitations in their production equipment. This is precisely where Eswoven's core strength lies—leveraging specialized production equipment to flexibly adjust fabric widths between 1.4m and 3.2m. This enables precise alignment with product dimensions.

For our customers, this capability means no need to alter proven, market-tested product dimensions to accommodate existing fabric specifications. You can maintain established product standards while we maximize cutting layout efficiency through flexible width adjustments. For Eswoven, this capability signifies a pivotal evolution in our role—transitioning from a mere “fabric supplier” to a “product development and cost optimization partner” for our clients. What we deliver to customers is no longer just fabric, but a customized integrated solution tailored to specific production needs.

Less Waste, More Profit: The Three Key Values of Custom Width

Directly Reduces Fabric Waste: Tailored widths enable highly compact cutting layouts, minimizing scrap to the lowest possible level. Every meter of raw material input is maximized into saleable goods.

Enhanced per-unit profit and market flexibility: Reduced waste directly lowers raw material costs per item, boosting gross margins without raising retail prices. It also expands pricing flexibility, granting greater control for promotions or enhancing product competitiveness.

Simplified Operations & Inventory Management: When fabric widths align precisely with core product specifications, there's no need to develop complex derivative sizes to utilize scraps. This allows for clearer product line focus and more accurate replenishment planning, reducing inventory risks and easing cash flow pressure.

Start Your Partnership: From Your Sizes to Our Solutions

It all begins with a simple starting point: provide the specific dimensions of your best-selling products, and we'll calculate the optimal production width for you. This goes beyond mere numerical matching—it involves deep layout analysis to plan the most efficient utilization path for every meter of fabric from the source. With flexible production capabilities spanning 1.4 to 3.2 meters in width, Eswoven is committed to delivering deep cost optimization solutions that go beyond standard supply.

In today's market landscape, enduring competitiveness stems from smarter supply chain collaboration. We aspire to be your true cost optimization partner—not merely a basic fabric supplier, but a collaborative ally working alongside you to unlock the profit potential within your supply chain.